The processes and functions of CCS

2025-08-08 17:40:46

2025-08-08 17:40:46

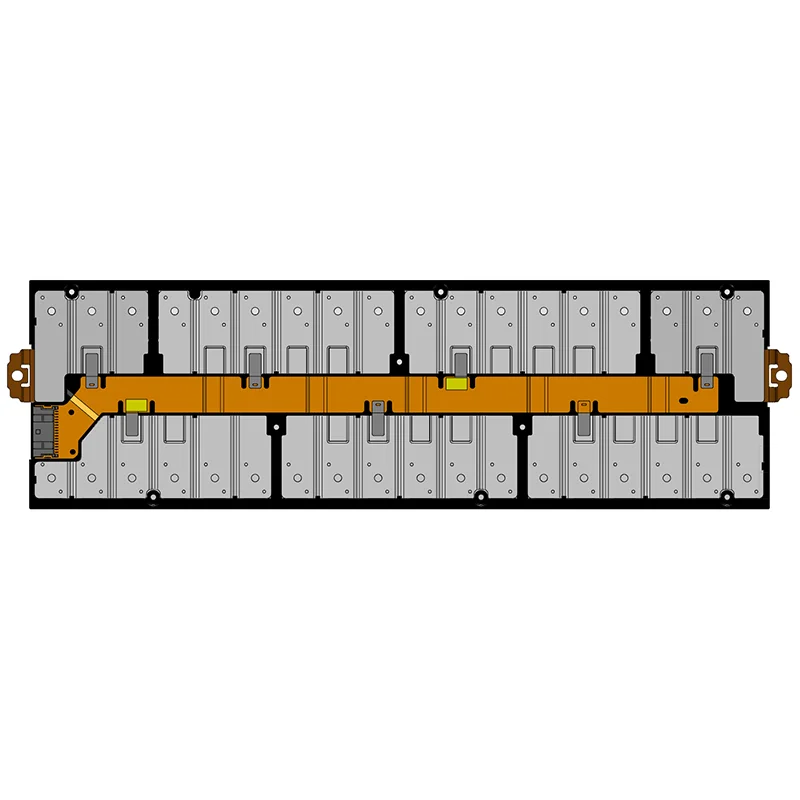

CCS (Cells Contact System), It mainly consists of signal acquisition components (FPC, PCB, FFC, etc.), plastic structural components, copper aluminium bars, etc., which are connected into a whole through processes such as hot pressing or riveting to achieve high-voltage series parallel connection of battery cells, as well as temperature and voltage sampling functions of batteries. Temperature and voltage are provided to the BMS system through FPC/PCB and connector components, which is a part of the BMS system.

The main process flow includes:

Incoming inspection → assembly of aluminum bars → placement of nickel sheets in corresponding positions → laser welding of nickel sheets and aluminum bars → placement on vacuum tray → single point hot riveting → cutting off excess zip ties → plastic wire harness → vacuum forming+wire harness processing → packaging and shipping

Compared to the traditional FPC hole board process that requires 21-30 steps, new methods such as FDC can be completed in only 2 steps, greatly improving efficiency and reducing pollution

Its function is reflected in:

Performance optimization: Good sealing, easy installation, reduced wiring harness connections, improved automation level, and saved labor costs.

Integration and light weighting: High integration makes the volume lightweight, saves space, achieves module light weighting, and supports modularization and standardization to reduce development costs.

Safety and monitoring functions: equipped with over current protection design, strong applicability, and integrated current/voltage sensors to collect real-time data, support communication and control, fault diagnosis, and improve battery management reliability.